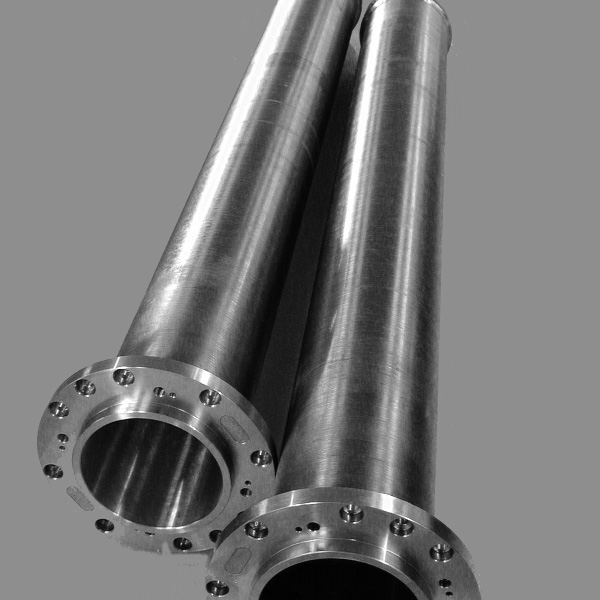

Seamless Tubes – Electrodeposited with High-Grade Nickel

Tubes for Scraped Surface Heat Exchangers

Tubes or cylinders for Scraped Surface Heat Exchangers made of electrodeposited high-grade nickel have some advantages over conventionally produced wrought nickel and stainless steel tubes. Though inexpensive and offering good machining, those tubes have poor heat conduction. Steel tubes have low corrosion resistance.

Heat exchanger tubes manufactured by ELEKTROFORM offer:

- better corrosion and thermal resistance

- lower internal stress --> better welding

- very good concentricity

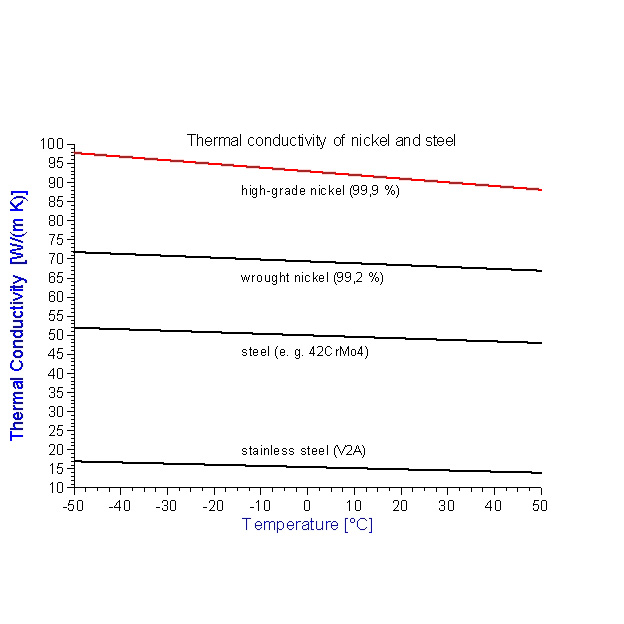

- better thermal conductivity (see picture below)

- wall thickness up to 10 mm

The purity of ELEKTROFORM´s high-grade nickel is approx. 99.9 % - wrought nickel has only 99.2 %. This difference may seem small. However, the following graph shows the difference in thermal conductivity.

Heat Exchanger Tubes: High-Grade Nickel in Comparison to Wrought Nickel, Steel and Stainless Steel

- much higher efficiency in heat ransfer -

For over a decade tubes manufactured by ELEKTROFORM have raised productivity, lowered production costs and helped delivering more uniform end-products for a wide range of processing industries (e.g. the food, chemical, petroleum, pharmaceutical and allied industries).

ELEKTROFORM manufactures heat exchanger tubes with a length of up to 3,500 mm and a diameter of 300 mm.