ELEKTROFORM Serves Europe's Leading Copper Producer

Usage of parts with high wear resistance

This part distributes 160 tons per hour of red-hot copper ore 365 days per year. In order to withstand extreme wear and corrosion, we electroplate these distributors with our newly developed nickel-cobalt-silica-carbide (NiCoSiC) coating. Therefore, ELEKTROFORM is able to improve the longevity of this vital part for its customer.

Distributor

Nickel Coating Withstands Liquid Steel

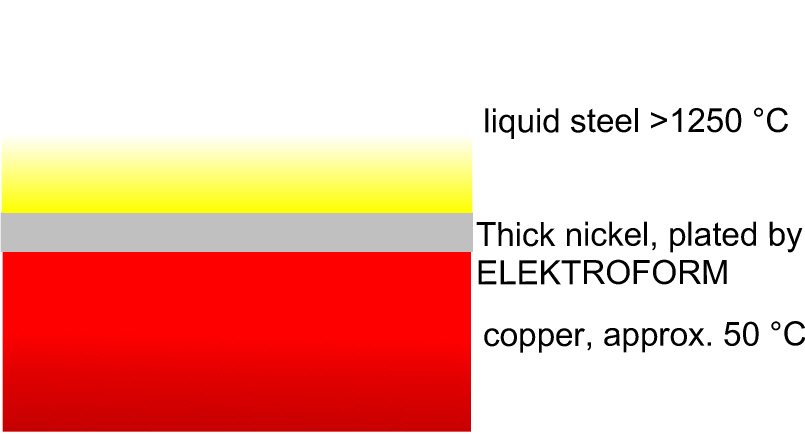

Copper molds are used in the production of steel. A thick nickel coating electrodeposited by ELEKTROFORM enhances the thermal and scales resistance. The perfect bond strength of nickel on the copper substrate results in a long-life expectancy for the mold.

Some characteristics of these extreme thermal conditions are:

- liquid steel with more than 1250 °C

- water-cooled copper mold with approximately 50 °C

The high temperature gradient induces enormous stress to the nickel coating and would peel off if the bonding was insufficient.